Fibre separation

Within the recycling sector, at Mavinil S.A., we also work with plastic products composed of multiple incompatible elements that cannot be recycled through shredding or milling, requiring a more complex reprocessing approach. They include fibre-based materials and double-layer materials.

After many years of hard work, we designed and developed our own machinery that separates plastic composites.

.

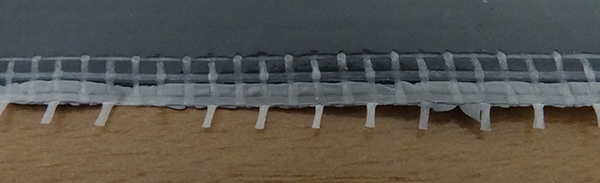

Fibre-based materials

At Mavinil S.A, we have developed an installation that recycles plastic materials containing textile fibres, primarily polyester, as well as cotton and polypropylene.

We separate the fibre obtaining clean plastic with a 0.001% impurity rate, ensuring maximum quality.

We work with materials from different sectors:

Waterproof sheeting, garden hoses, conveyor belts, advertising banners, etc.

The system we use is 100% mechanical and free from chemicals. This prevents the material from degrading, allowing it to be reused to produce the same material as before.

Double-layer materials

We recycle materials consisting of two layers where the base layer could be PP, PET, PVC, etc., and is usually 80% of the total. The second layer, which often acts as a film or lid is made of several materials (PM, EVO, PE, etc.) that cannot be recycled in the same way as the base layer.

Our system separates the film from the base so that the base can be reprocessed.

As with fibre separation, we use a 100% mechanical process that does not degrade the end material, making it fully reusable.

Many sectors generate double-layer materials, the most common being packaging for food, medicines and industry, etc.

The net product obtained is suitable for many sectors, such as manufacturing new sheeting, pipe bends, profiles, etc.

.